The Gregorio Marañón Hospital creates a surgical solution that combines augmented reality with 3D printing

La solución combina unas gafas Hololens con impresión 3D personalizada para que el cirujano disponga de una visión holográfica de las pruebas radiológicas del enfermo y reconstrucciones en 3D de su patología.

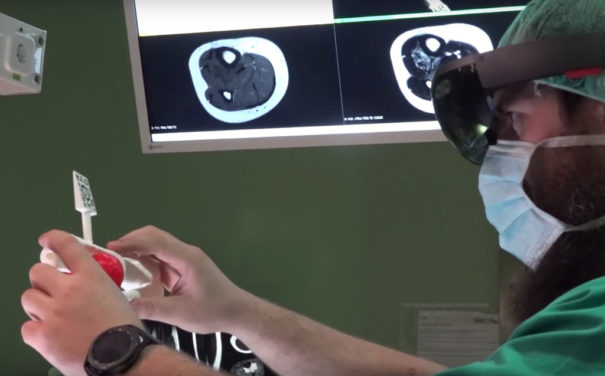

Cirujanos e ingenieros del Gregorio Marañón Hospital han desarrollado un sistema para quirófano, que combina el uso de gafas de realidad aumentada e impresión 3D personalizada, para proyectar sobre el paciente que va a ser operado hologramas de sus pruebas radiológicas, reconstrucciones 3D de su patología y la planificación quirúrgica.

Esta herramienta se apoya en un sistema de navegación muy preciso que permite identificar la postura del paciente en la mesa quirúrgica y desplegar las imágenes virtuales con un grado de exactitud submilimétrico. Es como si se dotará al cirujano de Rayos X mientras opera.

Esta herramienta se apoya en un sistema de navegación muy preciso que permite identificar la postura del paciente en la mesa quirúrgica y desplegar las imágenes virtuales con un grado de exactitud submilimétrico. Es como si se dotará al cirujano de Rayos X mientras opera.

Permite mejorar los resultados, minimizar los riesgos y acortar los tiempos de la operación. El reto de los sistemas de posicionamiento, navegación quirúrgica y realidad aumentada en quirófano era, until now, conseguir identificar la posición exacta del paciente para proyectar de manera automática y con suficiente exactitud la información virtual previamente procesada en el ordenador.

El Hospital Gregorio Marañón ha conseguido un desarrollo que permite proyectar los estudios radiológicos del paciente (TAC, RM, PET, etc.) directamente sobre el propio paciente con un margen de error submilimétrico, y esto se ha logrado gracias a la combinación de la tecnología de realidad aumentada con las gafas Microsoft Hololens de impresión 3D personalizada.

Gracias a la experiencia del hospital en impresión 3D (tecnología implementada en el centro desde el año 2015 y aplicada como herramienta de comunicación, simulación y planificación terapéutica por más de 18 especialidades médico-quirúrgicas del hospital) se identificó una solución que ha permitido sincronizar las imágenes 3D virtuales del paciente con el propio paciente real.

Este salto se consiguió con la impresión en 3D de una plantilla personalizada que incluye un marcador óptico que le indica a las gafas de realidad mixta dónde proyectar los hologramas 3D previamente generados.

Este salto se consiguió con la impresión en 3D de una plantilla personalizada que incluye un marcador óptico que le indica a las gafas de realidad mixta dónde proyectar los hologramas 3D previamente generados.

La plantilla se diseña en 3D en el propio hospital a partir de la reconstrucción del estudio radiológico del paciente (TAC, RM, PET), por lo que adapta en una posición determinada y únicamente en un paciente concreto, fabricándose con la forma anatómica exacta del paciente en el punto seleccionado.

Este proceso se realiza en el Laboratorio de Impresión del hospital donde se integra un marcador óptico a modo de patrón gráfico, que es reconocido por las gafas y que le indica al sistema dónde proyectar las reconstrucciones 3D deseadas.

Todo este sistema es como si se dotara al cirujano de Rayos X durante la intervención quirúrgica, ya que los estudios radiológicos se pueden proyectar sobre el cuerpo para construir sobre el paciente nuevas capas de información visual avanzada y le permite seleccionar el estudio radiológico u objeto 3D del paciente a modo de holograma.

Durante la operación los cirujanos pueden seleccionar, mediante comandos de voz o gestos, los modelos radiológicos y 3D que quieren que se proyecten sobre el paciente.

Se trata de un sistema de ayuda que aumenta la información anatómica y 3D del paciente durante la propia intervención, sin interferir con el normal procedimiento. La operación se realiza según protocolo quirúrgico habitual, pero contando con una herramienta de visualización avanzada que ayuda a acortar los tiempos quirúrgicos, minimizar los riesgos y mejorar los resultados.

Caso práctico

El Hospital Gregorio Marañón ya ha realizado una intervención con esta tecnología para extirpar un tumor en la pierna de una paciente, convirtiéndose en pionero a la hora de crear esa combinación de tecnologías y llevarla a una cirugía real, trabajando con esa información en el propio quirófano.

Besides, están trabajando para que cualquier smartphone con soporte de realidad aumentada pueda identificar el marcador integrado en la plantilla impresa en 3D y, sobre ella, proyectar la reconstrucción 3D en la pantalla del teléfono móvil. Esto resulta muy útil de cara a universalizar la aplicación y emplearla en entornos de simulación o formación médica a bajo coste.

El desarrollo se ha llevado a cabo mediante el trabajo colaborativo del Instituto de Investigación Sanitaria Gregorio Marañón, a través de un equipo interdisciplinar de investigadores liderado por los doctores Rubén Pérez Mañanes y José Antonio Calvo (cirujanos ortopédicos oncológicos) y Javier Pascau (director de grado de Ingeniería Biomédica de la UC3M), junto a la empresa madrileña 6DLab.

Did you like this article?

Subscribe to our NEWSLETTER and you won't miss anything.